Prefabricated Steel Structure Warehouse (BYSS-021)

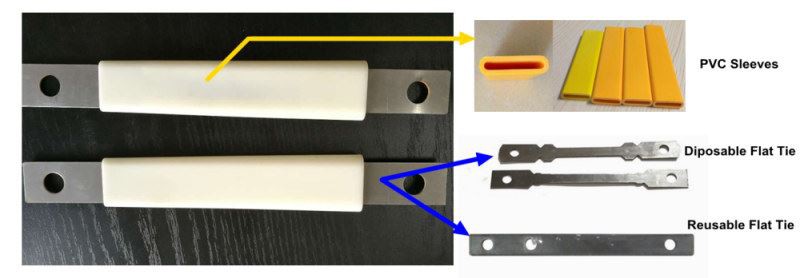

The flat tie rod is a thin steel plate whose length is determined by the thickness of the pilaster and is 2mm. During concrete construction, aluminum molds on both sides can be tightly "pulled" to prevent expansion and explosion of products during construction and ensure construction quality.

Product Introduction

Our high-quality R&D team always aims at international advanced technology, and constantly launches Rod Tie formwork System, Pin and Wedge for Formwork, Snap Ties Concrete forms with advanced performance and reliable quality. We shape the brand with global influence and excellent value, so we insist on global operation, quality-efficient operation and sustainable development goals. We always pursue the most perfect after-sales service, constantly improve the customer response mechanism, and reflect the professional and timely service tenet. At present, our factory has advanced production equipment and production technology. These superior conditions have enabled us to have many loyal users and partners, prompting us to keep moving forward. We will rely on our employees, customers, shareholders and social stakeholders to build a company that not only creates shareholder income, but also has a sense of social responsibility.

The flat tie rod is a thin steel plate whose length is determined by the thickness of the pilaster and is 2mm. During concrete construction, aluminum molds on both sides can be tightly "pulled" to prevent expansion and explosion of products during construction and ensure construction quality.

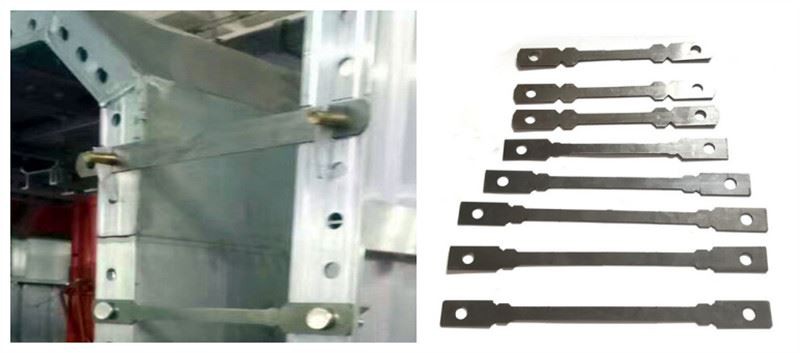

Tensile tests are carried out on each batch of high strength manganese steel to ensure that it can withstand a tensile force greater than 28kN.

Flat tie does not need to open holes on the panel, just milling grooves on the side ribs, and connecting the two forms with installation pins at the joint position. After the concrete has set, the aluminum formwork of the wall is removed, leaving a strip with two ends sticking out. Remove and extend the bow tie

Installation drawing

Schematic diagram (3)

It is designed as a v-shaped structure with stress concentration, and the fracture part is 5mm inside the wall, so there is no need to worry about the influence on the subsequent decoration process.

The distance between the base and the ground should not be greater than 200mm. A flat tie layout should be dense and sparse. Both sides are pressed flat with square holes to ensure flatness and hollow rectangular steel tubes.

The outer wall is provided with three square grooves, the third is arranged at the top K plate position. Install a small diagonal brace at the bottom to ensure a vertical installation. Sloping roof, top set wire rope, adjust verticality. Exterior walls are backed to prevent tilting.

We continue to undertake new projects in the technical field, accumulate rich experience, and lay a technical foundation for the research and development of new series of Prefabricated Steel Structure Warehouse (BYSS-021). The company has explored a set of business models suitable for its own development by learning from international companies, combining China's national conditions, pioneering and innovating. Integrity is the basis of being a human being, and it is also the basic guideline fused into the blood of every employee in the company.

Hot Tags: flat tie concrete modular, China, suppliers, manufacturers, cheap, quotation, low price, in stock, Rod Tie Aluminum Formwork System, Column Construction formwork Mold, Beam Panel Aluminum Formwork, Adjustable Prop, Struture Decking Concrete Slab, Townhouse Villa Aluminum Formwork

You Might Also Like

-

Factory Supply Slab Formwork Support Ajustable Shori...

-

Building Galvanizd Scaffold Push Pull Heavy Light Du...

-

Slab Formwork Support Ajustable Shoring Props Steel ...

-

Table Formwork for Slab Concrete Construction

-

Prefabricated Steel Structure Warehouse (BYSS-014)

-

Industrial Flat Roof/Low Cost Factory Workshop Steel...