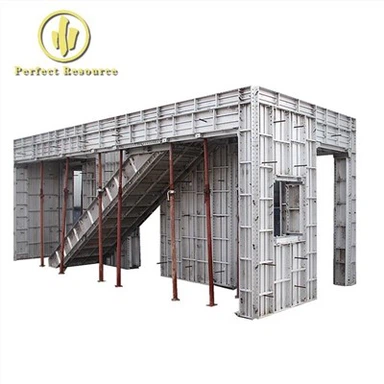

Wholesale Price Single-Side Bracket for Concrete Casting of Single-Sidewall for Dam ...

In order to speed up the construction progress, save the construction period, and reduce the workload of the tower crane equipment, combined with the actual situation of the project, the beam and floor slab formwork are installed as a whole; the aluminum alloy formwork support system adopts the quick disassembly construction technology; the formwork and its supporting materials are horizontally transferred The use of manual transportation reduces the workload of the tower crane.

Product Introduction

We promise to provide every customer with the most exquisite Long Pin for Drop Head, Lightweight Aluminum Formwork, Slab Table formwork that made by our professional production team under rigorous working attitude, as well as with the wholehearted service. We treat our customers, partners, shareholders and employees with integrity and take responsibility for the society. We have strong R&D, design and manufacturing capabilities, and our products are widely applicable to different customer needs. Talents promote the development of the company, and the development of the company provides a broader space and better conditions for the development of employees. Welcome all nice buyers communicate details of solutions and ideas with us!!

In order to speed up the construction progress, save the construction period, and reduce the workload of the tower crane equipment, combined with the actual situation of the project, the beam and floor slab formwork are installed as a whole; the aluminum alloy formwork support system adopts the quick disassembly construction technology; the formwork and its supporting materials are horizontally transferred The use of manual transportation reduces the workload of the tower crane.

The main construction sequence is as follows: leveling the structure, brushing the formwork release agent, formwork line-out, installation, positioning, straightening, beam and slab formwork installation; beam and slab formwork removal after concrete pouring; manual transfer to the next bid section through the loading port.

Aluminum alloy template installation

Acceptance and placement of aluminum alloy formwork materials.

1) After unloading, the template must be stacked according to specifications and dimensions. Divide the templates into a pile of 25 and place them on a shelf or pallet.

2) The templates should be stacked neatly according to the number for easy identification.

3). When stacking templates, make sure that the first template board at the bottom faces upwards.

4) All components such as pins, wedges, wall mold connectors, and special tools should be properly stored and distributed when needed.

We always rely on providing the most perfect Wholesale Price Single-Side Bracket for Concrete Casting of Single-Sidewall for Dam ... and the most perfect services to pursue the greatest customer satisfaction and thus realize the value of our enterprise! A brand is a symbolic representation of a company and its products, and the outward expression of a company's competitive advantage lies in its own brand. We actively promote modern management, intensive development and standardization, and promote the upgrading and transformation of product structure and raw material supply.

Hot Tags: easy disassembly tunnel formwork, China, suppliers, manufacturers, cheap, quotation, low price, in stock, Slab Table formwork, Beam Panel Aluminum Formwork, Aluminium Shuttering Formwork, Flat Tie Building Construction formwork, Lightweight Aluminum Formwork, Column Construction formwork Mold

You Might Also Like

-

Tie Rod Thread Rod Used for Aluminum Formwork Access...

-

Popular Structural Steel House Workshop Warehouse fo...

-

Formwork Props Adjustable Scaffolding System Height ...

-

Building Material Aluminium Alloy Formwork System fo...

-

Poplar Wood Making Circle Template as Concrete Wood ...

-

Lightweight Steel Flat Panel Formwork System