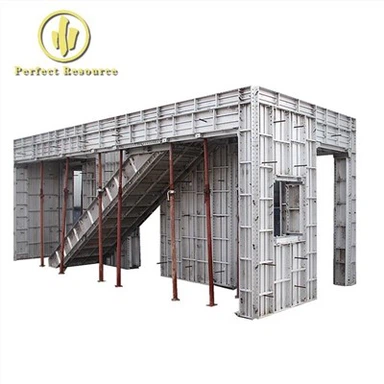

Customized Single Side Bracket Wall Steel Construction Formwork System for Trench ...

In order to speed up the construction progress, save the construction period, and reduce the workload of the tower crane equipment, combined with the actual situation of the project, the beam and floor slab formwork are installed as a whole; the aluminum alloy formwork support system adopts the quick disassembly construction technology; the formwork and its supporting materials are horizontally transferred The use of manual transportation reduces the workload of the tower crane.

Product Introduction

We pursue the management tenet of 'Quality is superior, Service is supreme, Reputation is first', and will sincerely create and share success with all clients for Long Pin for Drop Head, Column formwork, Adjustable Prop. We actively enhance the connotation of corporate culture, actively serve the development of the enterprise, and play an important role in promoting the image of the enterprise to the outside world. The company strictly establishes green production bases in accordance with the principle of strategic integration.

In order to speed up the construction progress, save the construction period, and reduce the workload of the tower crane equipment, combined with the actual situation of the project, the beam and floor slab formwork are installed as a whole; the aluminum alloy formwork support system adopts the quick disassembly construction technology; the formwork and its supporting materials are horizontally transferred The use of manual transportation reduces the workload of the tower crane.

The main construction sequence is as follows: leveling the structure, brushing the formwork release agent, formwork line-out, installation, positioning, straightening, beam and slab formwork installation; beam and slab formwork removal after concrete pouring; manual transfer to the next bid section through the loading port.

Aluminum alloy template installation

Acceptance and placement of aluminum alloy formwork materials.

1) After unloading, the template must be stacked according to specifications and dimensions. Divide the templates into a pile of 25 and place them on a shelf or pallet.

2) The templates should be stacked neatly according to the number for easy identification.

3). When stacking templates, make sure that the first template board at the bottom faces upwards.

4) All components such as pins, wedges, wall mold connectors, and special tools should be properly stored and distributed when needed.

The company currently has several outstanding partners who can provide strong support to the domestic Customized Single Side Bracket Wall Steel Construction Formwork System for Trench ... industry. We cultivate and practice socialist core values within our company and effectively implement the development concepts of innovation, coordination, green, openness and sharing. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

Hot Tags: easy disassembly tunnel formwork, China, suppliers, manufacturers, cheap, quotation, low price, in stock, Aluminum Formwork System, Mold Concrete Steel Concrete forms Ties, Snap Ties Concrete forms, Pin and Wedge for Formwork, Townhouse Villa Aluminum Formwork, Rod Tie Aluminum Formwork System

You Might Also Like

-

Concrete Formwork Adjustable Dw15/17 Tie Rod

-

Aluminium Construction Modular Formwork System for Sale

-

Feather and Wedges for Split Block

-

Tecon Slab Shuttering Scaffolding Frames Doka Formwo...

-

1500kg Shuttering Magnets Precast Products Aluminum ...

-

GF Steel Formwork Clamps Aluminum Formwork with Simp...