Concrete Construction Template PP Material 15mm 18mm

In order to speed up the construction progress, save the construction period, and reduce the workload of the tower crane equipment, combined with the actual situation of the project, the beam and floor slab formwork are installed as a whole; the aluminum alloy formwork support system adopts the quick disassembly construction technology; the formwork and its supporting materials are horizontally transferred The use of manual transportation reduces the workload of the tower crane.

Product Introduction

With a complete sales network, reasonable sales price and high-quality after-sales service, we are dedicated to providing high-quality New House Building Formwork System, Beam Panel Aluminum Formwork, Flat Tie formwork System and services for our customers. We develop and provide goods and services useful to society and contribute to the sustainable development of society In today's market conditions, demand is often changing, thus we need always pay attention to customer needs if we want to long-term development.

In order to speed up the construction progress, save the construction period, and reduce the workload of the tower crane equipment, combined with the actual situation of the project, the beam and floor slab formwork are installed as a whole; the aluminum alloy formwork support system adopts the quick disassembly construction technology; the formwork and its supporting materials are horizontally transferred The use of manual transportation reduces the workload of the tower crane.

The main construction sequence is as follows: leveling the structure, brushing the formwork release agent, formwork line-out, installation, positioning, straightening, beam and slab formwork installation; beam and slab formwork removal after concrete pouring; manual transfer to the next bid section through the loading port.

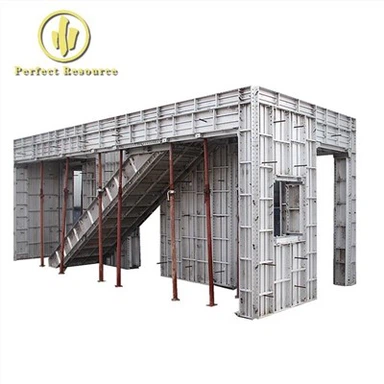

Aluminum alloy template installation

Acceptance and placement of aluminum alloy formwork materials.

1) After unloading, the template must be stacked according to specifications and dimensions. Divide the templates into a pile of 25 and place them on a shelf or pallet.

2) The templates should be stacked neatly according to the number for easy identification.

3). When stacking templates, make sure that the first template board at the bottom faces upwards.

4) All components such as pins, wedges, wall mold connectors, and special tools should be properly stored and distributed when needed.

Producing superb Concrete Construction Template PP Material 15mm 18mm and creating high quality brands is the pursuit of our enterprise as always, and it is our aim to constantly surpass and never stop. The company has invested in the establishment of a standardized and complete production plant and quality control center. The hardware investment in production and quality control has greatly improved the production capacity required for the company's continuous growth, and the product quality has been strongly guaranteed, which promotes the business to embark on a path of sustainable development. We actively promote the process of production automation and introduce several sets of automatic equipment to realize the automation of production operations.

Hot Tags: easy disassembly tunnel formwork, China, suppliers, manufacturers, cheap, quotation, low price, in stock, Villa Aluminum Formwork System, Aluminum Formwork, Aluminium Formwork for Standard Construction, Column Construction formwork Mold, Aluminum Formwork System, Villa Aluminum Formwork

You Might Also Like

-

China Supply Adjustable Steel Props for Slab Formwor...

-

Aluminum Formwork Strict Quality Control Aluminum Fo...

-

Steel Wood Customized Color Zulin Concrete Mould For...

-

Girder Slab Table Formwork Manufacture

-

Curved Wedge /Stright Wedge Doka Formwork Wedge

-

Forged Panel Clamp Scaffolding Formwork Accessories ...